With rapid turnaround times, competitive pricing, and high standards for quality and customer service, Inline Plastics, Inc. is an industry leader in custom plastic extrusions. Our team boasts more than 75 years of experience in research and development, quality control, and more. Since 1996, we’ve had the opportunity to work on projects for companies in a wide range of industries.

Agriculture

Inline Plastics creates custom grow tubes for grapevines, trees, and crops, which allow the plant to reap all the benefits of the sun and rain while being protected from chemical applications, foraging animals, careless human behavior, and more. Grow tubes encourage vertical growth while creating a greenhouse effect that can prolong the growing season in cooler climates.

Our grow tubes are manufactured according to your needs:

- Shape: A circular grow tube diffuses light and minimizes heat absorption, while a square or triangular version will retain more heat—a critical consideration when growing heat-loving plants in a cooler climate or when helping a young plant survive a hot, dry summer.

- Wall Thickness: Grow tubes can vary in thickness and opacity, an adjustment that allows you to better meet the sunlight needs of a particular type of plant or vine.

- Length: A long grow tube can support a sapling as it grows established or protect older trees from deer and other animals. Shorter grow tubes are more appropriate for small crops or new vines.

Automotive

Cars and trucks require a variety of precision components for both functional and decorative purposes. Many of them are produced via plastic extrusion profiles, including windshield wipers, hoses, decorative trim, and weather stripping. Even the seats in a car rely on plastic extrusion for seating retainers and the stiffeners that keep the seats upright. These durable, lightweight components help vehicles meet expectations for fuel efficiency and affordability.

Construction & Roadwork

Like automotive, the construction industry relies on custom plastic extrusion for a number of products, from structural components and vinyl siding to water and sewer pipes, fencing, decking, rain gutters, weatherstripping, and window extrusions. For road construction as well as fixed construction zones, road delineators help direct traffic and keep workers safe—and with plastic extrusion, they can be customized to meet the needs of your worksite.

Inline Plastics is proud to create custom solutions that allow construction companies to build cost-effective homes, offices, and other structures with reliable components that enhance safety, functionality, and aesthetics.

Consumer Products

For years, companies have turned to plastic extrusion to create toys and playground equipment, exercise equipment and sporting goods, audio/visual components, appliances, electronics, safety equipment, and more. Thermoplastics are lightweight and affordable, especially when compared to many alternative materials like wood and metal. With a range of plastics to choose from, plastic extrusion is especially versatile and can be used to create reliable components for applications within this broad category of products.

Food & Beverage

Using materials like flexible and rigid vinyl, HDPE and LDPE, polycarbonate, polyurethane, and many others, Inline Plastics serves the food and beverage industry with carefully designed products that can withstand high temperatures, chemicals, and high or variable pressure while meeting regulations and standards for sterility.

Items like vinyl tubing and pipes, drinking straws, jars, and bottles can be customized in your choice of color, load capacity, resistance to corrosion or specific chemicals, strength, and more.

Industrial/Manufacturing

From transportation and agriculture to furniture, healthcare, and research, the need for custom plastic extrusions continues to grow. Manufacturers rely on Inline Plastics to create precise components that meet industry regulations and rigid application demands, which is what we’ve been doing for years. With an experienced team of designers, technicians, and client care representatives, we’re prepared to handle your most complex requests.

Lighting

Inline Plastics manufactures LED lenses along with the various components for lighting fixtures. Choose the best material for your needs: acrylic lenses offer excellent clarity, and they won’t turn yellow over time, while polycarbonate is tough enough to withstand extreme high-impact applications.

Medical

From catheters and feeding tubes to IVs and oxygen tubes, medical tubing must meet strict healthcare standards for cleanliness and sterility, safety, and reliability. At Inline Plastics, we work with FDA-certified materials, including Class VI radiation sterilizable materials, for medical applications. We work with our clients to help them determine the best profiles and designs and choose the polymer that offers the properties required for a specific application.

Plumbing/Water Treatment

Reliable piping is a must for water filtration, sewage treatment, water aeration, water storage, and more. Starting with U.L. and NSF-approved materials, we manufacture custom tubing for plumbing and water treatment applications.

Signage

Signage is always a fun project, as it’s an opportunity to combine form and function into a creative result that’s ideal for your brand. With unique colors and finishes available on a range of thermoplastics, we can help you choose a combination that can withstand environmental conditions while displaying your message clearly and effectively both indoors and outdoors. You’ll see our work at fast-food restaurants, grocery stores, gas stations, and more.

Hydroponics

The hydroponics industry must use food-safe plastics that won’t leach chemicals into the water, like PET and food-grade HDPE. Plastic extrusions include grow tubes, hoses, nutrient tanks, and more.

Laminate/Adhesive Cores

Inline Plastics has years of experience working with the highly specialized composites used in the laminate and adhesive core industry.

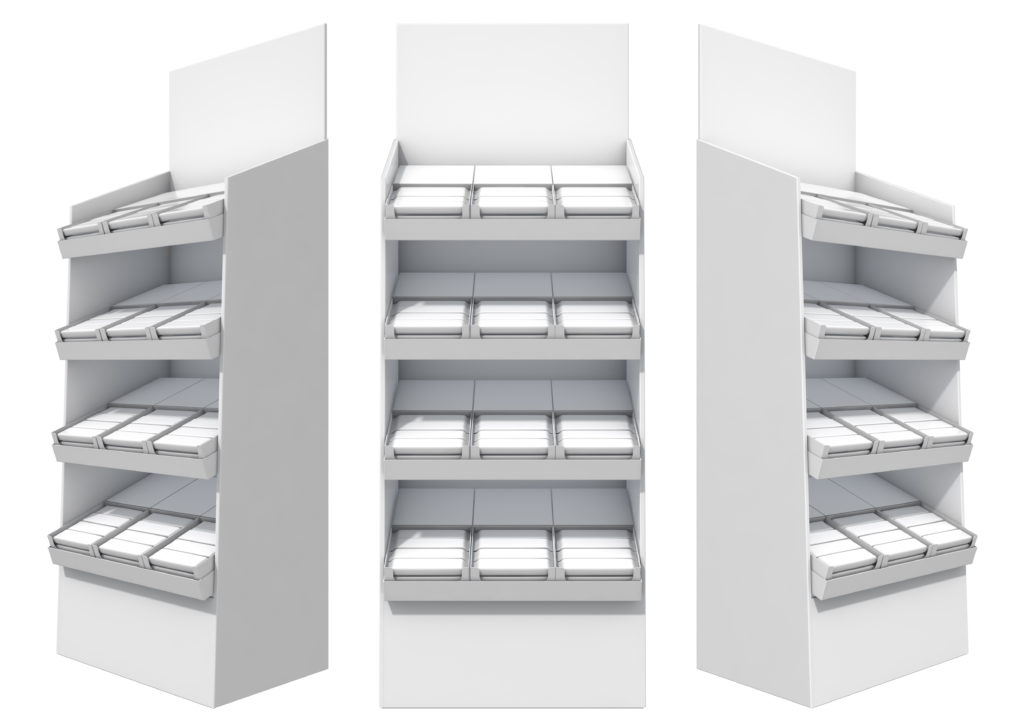

Point-Of-Purchase Displays

A POP display is an essential sales tool that can be customized to meet your brand’s personality and encourage consumers to try your product. Our plastic extrusion profiles for point-of-purchase displays include:

- Shelf Edging

- Shelf Talkers

- Label and Sign Holders

- Bumpers

- Shelf Caps

- Edge Trim

- And More

Off-Road Vehicles

Plastics are as rugged and durable as the off-road industry demands. ATVs, SUVs and other off-road vehicles rely on plastic extrusion as much as your typical commuter car does. By choosing the right plastic for the job, you meet your requirements for durability, impact resistance, corrosion resistance, and more in a cost-effective way. Plastic components are relatively easy to engineer and replace, so you have a long-lasting part that can be affordably replaced if needed.

Pet Products

Plastic extrusion is used to make a variety of pet products, including chew toys, toy bones, and even aquarium parts (for both fish & reptiles). Extrusion is also often used for making dog and cat door parts. Careful material selection and engineering ensures that your pet can enjoy a non-toxic environment and products that are free from harmful dyes and additives.

Custom Plastic Tubing And Profile Extrusion Services At Inline Plastics, Inc.

No matter your industry or application, Inline Plastics, Inc. can help with all your plastic extrusion needs. From custom plastic profiles and plastic tubing to plastic extrusion die development, quality control, and research and development, our experienced team offers personalized customer care that ensures our products meet or exceed your expectations. We offer competitive pricing and fast turnaround, which starts with sending you a quote within 30 minutes for most projects. Simple dies can be ready to go in as little as two days.

Request a quote for your project or contact us to learn more about plastic extrusions, our range of secondary operations, and the 20 thermoplastics we can use to meet your exact specifications.